The Global Protein Challenges

Pressing challenge to produce more sustainable protein.

The human population has never increased so quickly. Today, we are 7.7 billion people on earth. By 2050, we will be 9 billion. We will need to produce more food in the next 50 years than in the past 10,000 ones, in particular, 70% more animal protein will be needed to satisfy the global demand. We therefore urgently need to find new sources of proteins that are more sustainable and environmentally friendly, for both human consumption and livestock feed. It is possible if we start acting now!

Increasing pressure on scarce resources.

The current livestock system is responsible for the emission of 7 gigatonnes of CO2 each year, which amounts to 15% of human-induced greenhouse gas emissions according to the Food and Agriculture Organization of the United Nations.

70% of farmland is used for livestock farming, which is one of the main reasons for deforestation. Moreover, aquaculture requires large amounts of fish meal, which, in turn, is responsible for overfishing and the degradation of marine ecosystems.

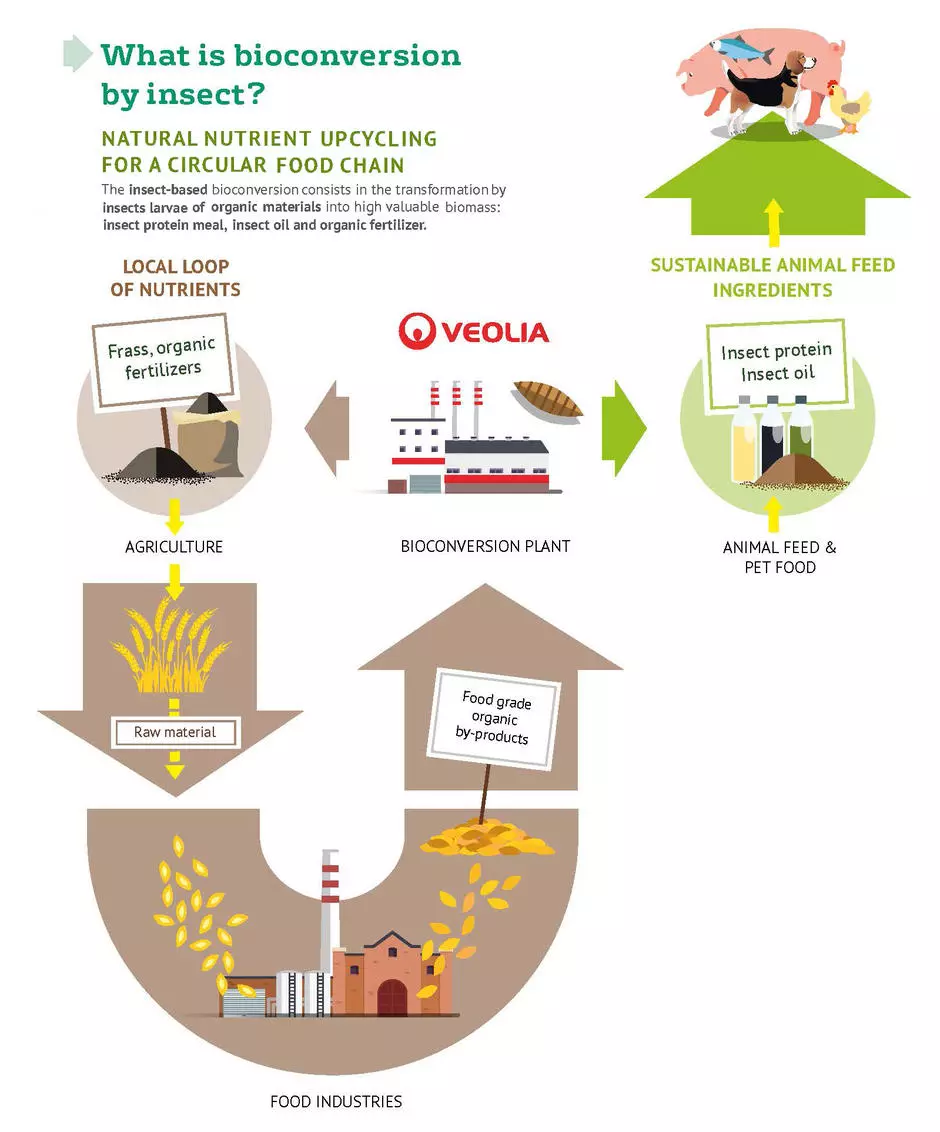

Finding A Sustainable Alternative Solution: Bioconversion By Insect - Black Soldier Fly

ENTOFOOD: The Pioneer In The Industry

THE GAMECHANGING IDEA OF FRÉDÉRIC AND FRANCK,

CREATING ENTOFOOD IN 2010.

In 2010, Frédéric convinced Franck to join the project. Franck was a shrimp farmer with a deep understanding of the aqua-industry challenges. They started their experiment in a small laboratory in Madagascar, and called it Entofood, envisioning a new source of feed coming from insects.

At the time they met Emilie Devic, who was among the very first scientists in the world specialized in Black Soldier Fly (Hermetia illucens B.S.F.) farming and its application in aquafeeds. Inspired by the ambition of Frédéric and Franck, Emilie joined Entofood in 2016.

At the end of 2011, they spotted South-East Asia for their pilot farm, where there is the largest aquaculture market (more than 80% of the world production).

Entofood & Veolia Joining Forces

Entofood and Veolia joined forces to contribute to providing a sustainable solution enhancing the circularity in the Food Chain in the Year 2017.

From 2018 to 2020, they successfully scaled up the Bioconversion technology and delivered Veolia Bioconversion Malaysia plant, Veolia’s first industrial-scale insect facility into production.

Today Veolia Bioconversion Malaysia plant has the capacity to produce 3000 tons of insect meal per year and is already providing insect ingredients to different animal nutrition markets.

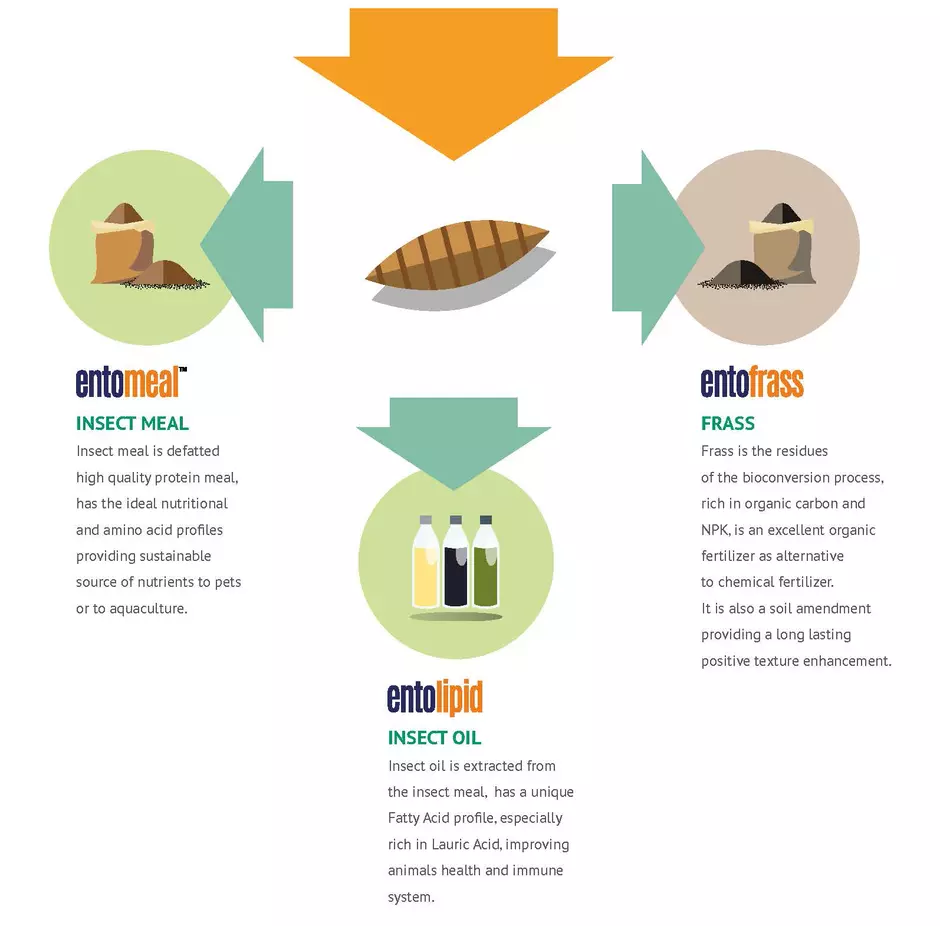

Our Products Through Bioconversion Process

Veolia's Commitment

Purpose

This vision of building a healthier world aligns with Veolia’s mission to become the champion of ecological transformation: Transforming the agricultural sector is one strategic pillar of Veolia’s ambitions.

Commitments

The Malaysian plant is a Veolia-owned plant, and thus a robust and stable partner to work with. We aim to meet our clients’ needs by delivering consistent quality products and compliant with the highest standards.

Making A Difference

Quality Reassurance

Successfully operating at an industrial scale, the Veolia bioconversion plant provides stable and consistent products. The larvae and flies' health and environmental conditions for growth and rearing are closely monitored for tracking and optimization.

Sourcing Expertise

With its 160 years of resources management history, Veolia has built a strong relationship with Food & Beverage industrial entities providing direct access to various types of feedstock and developing worldwide expertise in organic by-products valorisation.

Functional Performance

Entomeal provides a good source of the essential amino acids such as histidine, phenylalanine, threonine, tryptophan and valine and the conditionally essential amino acid tyrosine.

Sustainability

- No arable land is needed for production

- BSF is a natural nutrient recycler due to its detritivore nature

- Upcycling organic side streams (e.g. brewery waste)

- Preserve terrestrial and marine biodiversity

- Bioconversion is an industry with zero waste

- Minimal water requirement

- Non-invasive & non-vector of diseases

Certified With Quality Assurance

Veolia Bioconversion plant in Malaysia adheres to the highest industrial standards and the most stringent regulation requirements ensuring a consistent, premium product,entomealTM (insect meal) and entolipid (insect oil) with full traceability from black soldier fly eggs to finished products.

The facility has undergone and passed ISO 22000 and GMP+ certifications. Farmed with zero-waste methods, the larvae are freshly processed after harvest ensuring premium quality, nutritious, safe and sustainable alternative protein and functional ingredients in pet food and animal feed industries.

Press Release and Articles

Veolia’s Entomeal®, insect meal & Entolipid, insect oil now reaches Europe

Veolia Bioconversion Malaysia Sdn Bhd received approval from the Ministry of Agriculture in Malaysia to export Entomeal®, insect meal and Entolipid, insect oil into the European markets for use in pet food, aquaculture and livestock.